Products

It’s a concrete fact:

THE ONLY WAY TO GET THE EXACT RIGHT MIX, AND EXACTLY THE CORRECT AMOUNT IS TO MIX YOUR CEMENT, AGGREGATE AND WATER ON-SITE.

Titan Volumetric mixers

Made with Hardox® 450 steel, the Titan mixer is built to last with double the expected lifespan and experiencing 612 KG of weight savings.

commonly used by:

Concrete

Mining

Defence

Landscaping

Construction

Volumetric mixers

Volumetric mixers save you the trips back to the batch plant, and make sure that the concrete you pour is the exact mix the job requires.

commonly used by:

Concrete

Utilities

Defence

councils

transport

Construction

Unit Features

Standard

The outlet and metering of the Aggregate and Sand in our mixer is design so that material can come out in as close to a perfect cube as possible – this means your aggregate usage is extremely accurate and your concrete is always perfect.

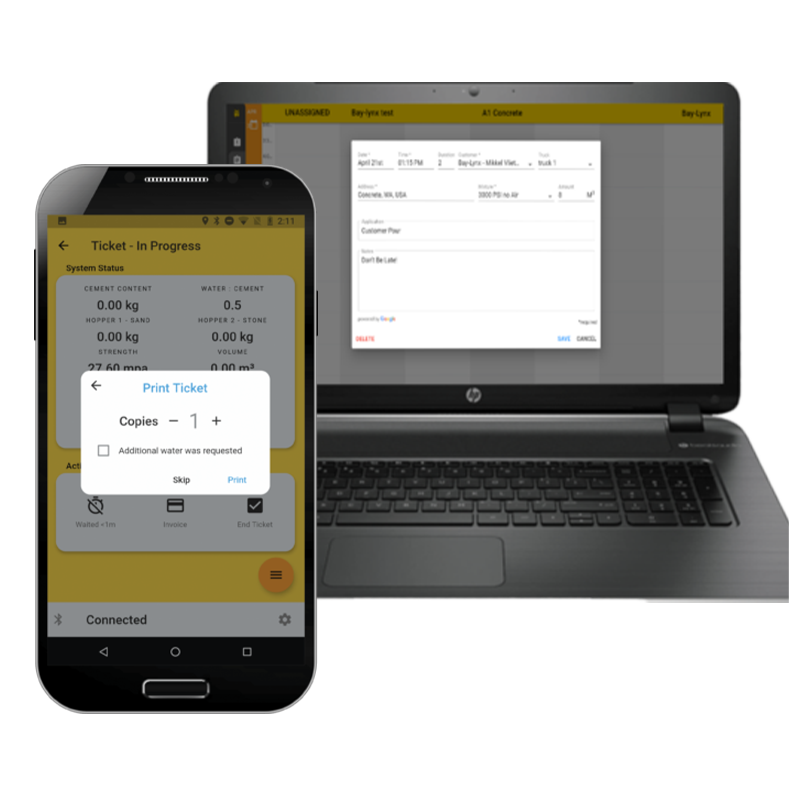

The software solution provides a web customer order portal, a dispatch software and a mobile application for your operator to track everything on the mixer.

With the hydraulically linked cement and feed belt, you can experience pour speed flexibility for nearly any mix design.

Our water system is designed to give you lower pressure when you are producing concrete and then when you are washing up you will be able to get up to and over 100psi of pressure, allowing you to keep your unit looking the sharpest in the market.

The wireless remote is great for your operator because he can now be more productive while on the job-site and ensure the customer is getting the service promised.

* For Titan Mixers only.

Optional

We have successfully developed and employed on numerous units a liquid color admix system that provides extremely accurate and repeatable colors. this means you can become the preferred color concrete supplier of choice in your market.

Health and safety is always a concern. We are able to add dash cams and rear view cameras to help ensure the safety of your staff and those around the job site and when in transit.

Perhaps your require more specialty concrete using liquid admixtures. Not a problem more can be added. Ask us more when requesting a quote.

We have partnered with Lube Core and can offer a complete auto greaser system for your chassis and mixer. Auto greaser systems take most of the concern away regarding longevity and maintenance. Ask us more when you request a quote.

FAQ’s

Both a concrete plant with ready-mix drum trucks and volumetric concrete mixer produce quality concrete however, there are some distinct advantages to choosing a volumetric mixer.

i. Customer only pays for exactly what they need: Because the VCM is in essence a mobile concrete batching plant if the customer needs a little more or a little less then what they originally thought it is not a problem because production stops when the job is done. With Ready-mix drum trucks the customer has to make an accurate estimate of what is needed because it is batched and water is added at the plant then delivered to the site.

ii. Concrete is ALWAYS Fresh: With a VCM the concrete is made fresh every second as it is being produced so the newest concrete is what is being laid. With concrete from a drum truck the concrete coming out last is the oldest and may already be stiff.

iii. Small quantities are not a problem: With a VCM you can produce as little as a quarter of a cubic meter or yard of concrete and then pack up and go to another job. With traditional drum trucks, this becomes almost impossible and very uneconomical. After a small load, the drum truck also has to return to the plant to reload for the next job.

iv. Multiple mixes in one stop: With a VCM the operator can do a variety of concrete mixes in one stop. For instance, perhaps a sidewalk had to be removed to get at some utilities. A VCM could then produce some fill concrete to cover the utilities and bring the grade to underside of sidewalk slab height. Then the slab could be formed up and the VCM could produce the correct concrete for the sidewalk slab as well without have to return to the job site.

v. Time is not a factor: With a VCM the problem of time does exist. Concrete in a delivered in a drum truck is exposed to water at the plant and is now perishable and the time to get it delivered and into position is less than 2 hours. With a VCM you can deliver concrete an infinite distance away. With a VCM you can be stuck in traffic and still deliver fresh concrete to the customer. With a VCM delays on the job are much less stressful.

vi. Evenings and Weekends: To open a traditional batch plant after hours or on the weekends can cost thousands of dollars and require a minimum quantity of concrete to be ordered. With a VCM anytime and any day is just like any other.